A Guide to Manufacturing High-Quality Wet Mops

Introduction:

Mops are an indispensable tool for maintaining cleanliness and hygiene in various settings, from households to commercial spaces. Manufacturing these essential cleaning tools requires careful planning, the right equipment, and top-quality raw materials. In this blog post, we will explore the basic requirements and the step-by-step process involved in manufacturing wet mops that meet market demands and exceed customer expectations.

Identifying and Selecting Cleaning MOPs

Before diving into the manufacturing process of wet mops, it is crucial to identify and select the types of mops you wish to produce and introduce to the market. This step sets the foundation for your business’s success as it directly aligns your products with your target market’s needs and preferences.

Conduct thorough market research to understand the demand for different types of mops in various settings, such as households, offices, hospitals, or industrial facilities. Consider factors like material preference, size requirements, and specialized features that customers may be looking for in a wet mop.

Once you have a clear understanding of your target audience’s needs, narrow down your selection to a few key types of mops. For example, you may choose to focus on traditional cotton yarn mops for general cleaning, microfiber mops for enhanced absorbency and dust trapping, and polyester-cotton yarn mops for a balance of durability and cleaning efficiency.

By offering a diverse range of mops, you can cater to a broader customer base and stay competitive in the market. Additionally, keep an eye on emerging trends and innovations in the cleaning industry to adapt your mop selection accordingly and ensure you stay ahead of the competition.

Injection Molding Machines and Molds

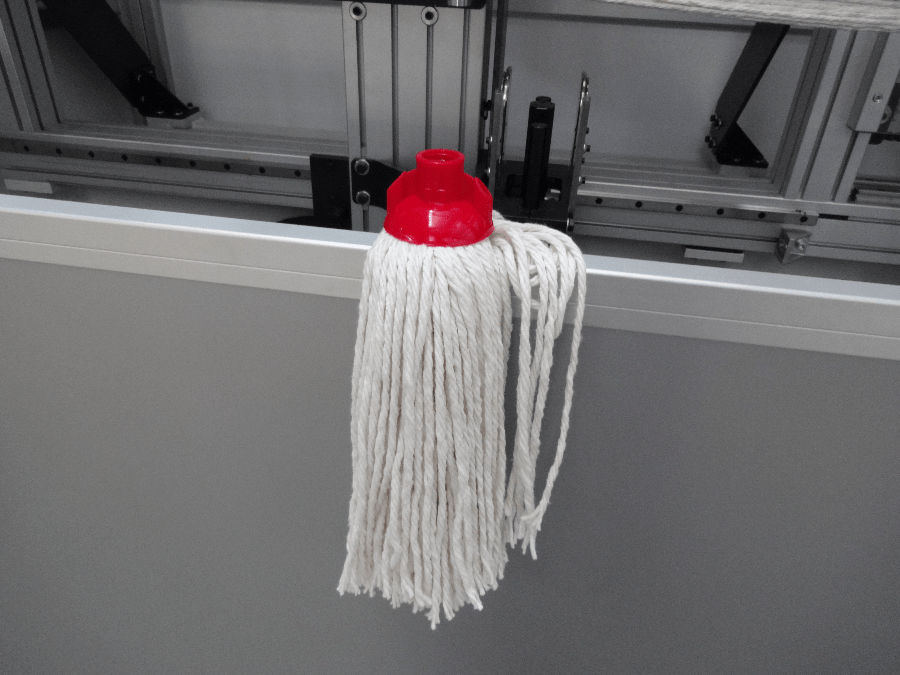

Once you have finalized the mop design and identified the plastic clips as a crucial component, the next step is to acquire injection molding machines and create custom molds. These machines will enable you to manufacture the upper and bottom plastic clips that securely hold the mop yarn in place, ensuring the mop’s longevity and effectiveness.

Invest in high-quality injection molding machines that offer precision and efficiency in the molding process. Custom molds should be designed to match the specifications of your mop design and size requirements. Most importantly the clips must be free from flash and shrinkage to offer a producer nonstop productivity. Also ensure that the clips fit the mop perfectly, preventing any potential issues during use.

Collaborate with skilled mold designers and manufacturers to create durable and well-finished molds. Proper maintenance and regular inspections of the molding equipment are essential to ensure consistent output and reduce the risk of defects in the clips.

MOP Making Machine

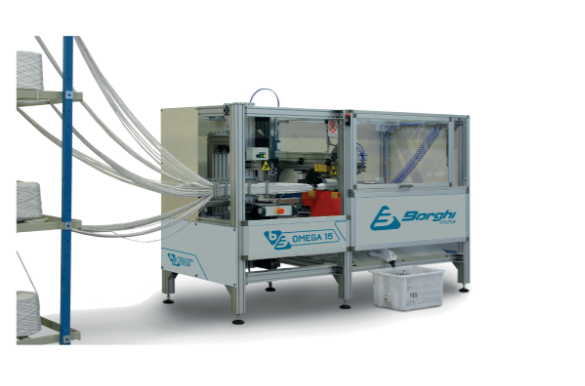

The heart of the wet mop manufacturing process lies in the mop making machine. This specialized equipment brings together the plastic clips and the selected yarn materials to form the final product.

Invest in a state-of-the-art mop making machine that automates the assembly process, guaranteeing uniformity and efficiency in production. The machine should be versatile and capable of accommodating various mop designs and sizes, allowing you to adapt to changing customer demands.

Hire skilled machine operators who are well-trained in handling the equipment and can troubleshoot any issues that may arise during production. Regular maintenance and calibration of the machine are essential to ensure its optimal performance and prolong its lifespan.

Air Compressor, Stabilizer, and Supporting Equipment

To ensure the smooth operation of the mop-making machine, it is essential to have the right supporting equipment in place. Two crucial components are the air compressor and the stabilizer.

Air Compressor: The mop-making machine often relies on pneumatic components to function effectively. An air compressor provides the necessary compressed air to power these components. Investing in a reliable and adequately sized air compressor will ensure consistent and efficient operation, reducing downtime and production delays.

Stabilizer: A stable power supply is vital for the safety and performance of the mop-making machine. Voltage fluctuations and power surges can damage the equipment and disrupt production. By using a stabilizer, you can regulate and stabilize the electrical voltage, safeguarding the machine from potential electrical issues.

Apart from the air compressor and stabilizer, other supporting equipment, such as cleaning and maintenance tools for the machines, should also be readily available to ensure smooth day-to-day operations. Regular maintenance checks and servicing will extend the lifespan of the equipment and prevent unexpected breakdowns.

Basic Raw Materials Required

The quality of the wet mop directly depends on the choice of raw materials. It is essential to source top-notch materials to manufacture mops that meet or exceed customer expectations.

Cotton Yarn: Cotton yarn is a classic and widely used material for wet mops. It offers excellent absorbency and is ideal for general-purpose cleaning. Cotton yarn mops are suitable for various surfaces and are often preferred for their durability.

Polyester-Cotton Yarn: Blending polyester with cotton yarn adds strength and resilience to the mop. Polyester-cotton yarn mops offer improved durability and can withstand more extensive use in commercial and industrial settings.

Microfiber: Microfiber mops have gained popularity in recent years due to their superior absorbency and dust-trapping capabilities. They are highly effective in capturing small particles and germs, making them an excellent choice for cleaning in healthcare facilities and areas with stringent hygiene requirements.

By carefully selecting and sourcing these raw materials, you can manufacture wet mops that cater to different cleaning needs and preferences, further establishing your brand’s reputation for quality and performance.

Stick/Handle Materials

The stick or handle of the wet mop plays a significant role in its usability and durability. Different materials offer various advantages, and the choice depends on factors like budget, target market, and intended use.

Steel: Steel handles are sturdy and offer excellent longevity. They are a popular choice for heavy-duty mops used in industrial environments or areas with high foot traffic.

MS Coating: Mild steel handles with a protective coating provide corrosion resistance, making them suitable for mops used in humid or wet environments.

Wood: Wooden handles are lightweight and often preferred for household cleaning. They offer a comfortable grip and are aesthetically pleasing.

PVC: several stick producers offer stick from PVC / CPVC material, whereas this is a workable option the cost of material does not offer an economical solution.

Manufacturers can choose to outsource stick/handle production or import them, depending on availability and cost-effectiveness. Ensuring the stick/handle materials meet ergonomic standards will enhance user experience and reduce strain during cleaning tasks.

Packing Materials

Once the wet mops are manufactured and ready for distribution, appropriate packing materials are essential to protect the mops during transportation and storage.

Poly Bags: Individual mops can be sealed in poly bags to prevent dust and moisture from compromising their cleanliness.

Cartons: Cartons provide a sturdy and safe packaging solution for multiple mops, ensuring they are well-protected during transit.

The packaging should be designed to be efficient and eco-friendly, reflecting your commitment to sustainability and reducing environmental impact.

Space, Power, and Labor

Establishing a suitable manufacturing facility is vital for efficient production. The space should accommodate the machines, storage for raw materials, and finished products. Additionally, ensure that the facility adheres to safety regulations and allows smooth workflow.

An uninterrupted power supply is crucial for maintaining productivity and preventing damage to the machines. Backup power sources should be in place to tackle any unexpected power outages.

Lastly, skilled labor plays a crucial role in the manufacturing process. Train your workforce to handle the equipment, maintain quality standards, and troubleshoot potential issues. A well-trained team will contribute to the success of your wet mop manufacturing venture.

Conclusion:

Manufacturing high-quality wet mops requires a comprehensive understanding of customer needs, investment in advanced equipment, and sourcing top-notch materials. By adhering to the essential requirements and following a step-by-step process, you can produce wet mops that meet market demands and establish your brand as a reliable provider of efficient cleaning solutions. With the right mix of product diversity, quality, and customer service, your wet mop manufacturing venture is well-positioned for success in the competitive cleaning industry.