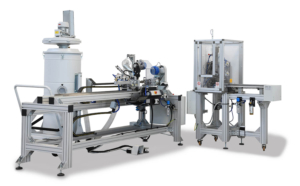

A twisted wire brush making machine is a great investment for any manufacturer looking to add this type of product to their lineup. SIGMA machine is perfect for creating twisted wire brushes of all sizes and types, and it is incredibly easy to use.

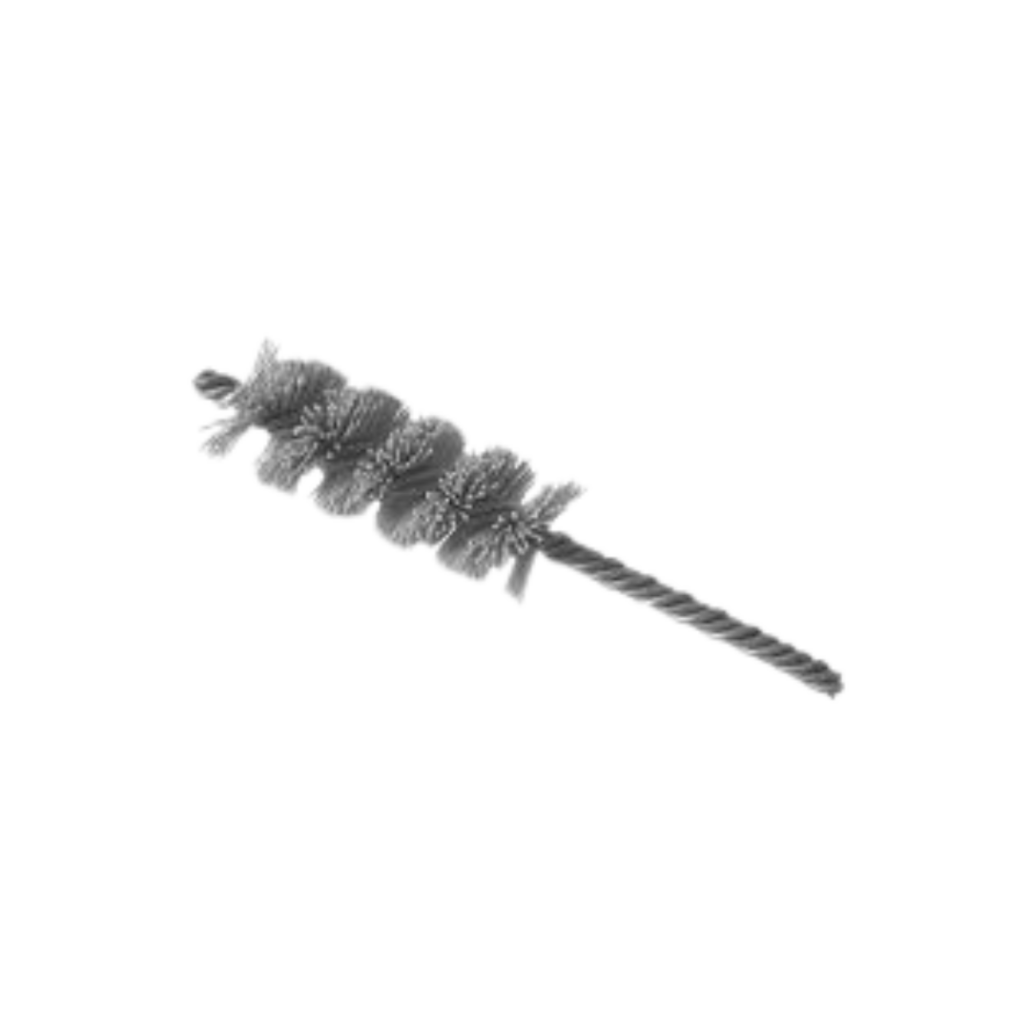

Twisted wire brushes

There are many reasons why you might need a twisted wire brush. One of the most common reasons is because traditional wire brushes can be very inefficient when it comes to removing dirt from a curved surface. Twisted wire brushes can be more effective at doing this because the bristles are held together tightly, which means that they can remove more dirt with each stroke.

Twisted Wire Brush Making Machine

Are you looking for a machine that can produce loop-end, closed-end or cut-end (open) twisted wire brushes? Look no further than the SIGMA machine! This versatile machine is composed of a clamping unit that twists the stem wire, a hook unit (or second clamping unit, optional) that holds the stem wire under tension, and a trimming unit to trim the fibers.

The SIGMA is usually combined with a Filament Setter, which prepares the tufts of fiber to be manually inserted in-between the two stem wires. The SIGMA can work with synthetic, natural and metallic fibers, as well as metal stem wire and plasticised wire.

How does a Twisted Wire Brush Making machine work?

The machine works by first clamping the stem wire in place. Then, a hook unit (or second clamping unit, if required) is used to hold the stem wire under tension. After this, the trimming unit is used to trim the fibers so that they are symmetrical and the shape looks aesthetically good. Finally, the brush is complete to use.

Features of Twisted Wire Brush Making machine include:

- The ability to produce brushes with synthetic, natural, or metallic fibers/filament.

- The ability to use metal stem wire or plasticized wire.

- The ability to produce brushes with either loop-end, closed-end, or cut-end (open) bristles.

- The ability to trim the bristles to the desired length.

- The ability to produce a variety of different brush types

- Works with a variety of different materials

- Can be combined with the Filament Setter for ease of use

- The machine is simple to use and easy to handle.

- The machine is durable and long lasting.

Benefits of using a Sigma machine include:

- Increased productivity

- Reduced labour costs

- Consistent quality

- Greater flexibility in design

- Ability to produce customised brushes

If you are in the market for a machine that can produce twisted wire brushes, the SIGMA is the perfect choice!

Applications:

The machine is used to make brushes for industrial and commercial applications. It can be used to make brushes for cleaning bottles, cans, pipes, and other objects. The machine is also used to make twisted wire brushes for various applications such as polishing, brushing, and scrubbing.

Technical Specification of Sigma Twist Brush Making Machine

| Brush Length upto (mm) | 600 |

| Brush Diameter Range (mm) | 30…..200 |

| Max. Wire Diameter (mm) | 4.0 |

| Min. Wire Diameter (mm) | 0.7 |

| Power Consumption (kW) | 0.2 |

| Air Consumption (nL/min) | 40 |

| Weight (kg) | 250 |

| Dimensions (mm) | L-1500W-800H-2100 |

Twisted in Wire Brushes Examples