Toilet Brushes Buying Guide 2022

How to Choose the Right Toilet Brush for Your Home

Toilet brushes are an essential tool for keeping your toilet clean. But with so many different toilet brushes on the market, how do you choose the right one for your home? It would help if you considered several factors while buying a toilet brush. E.g.

- What type of bristles does the brush have?

- What is the shape and size of the brush?

- How easy is it to clean?

In this buying guide, we will discuss all of these factors and more so that you can choose the right toilet brush for your home. We’ll also provide tips on using a toilet brush effectively and keeping your bathroom clean!

Factors To Consider When Buying A Toilet Brush

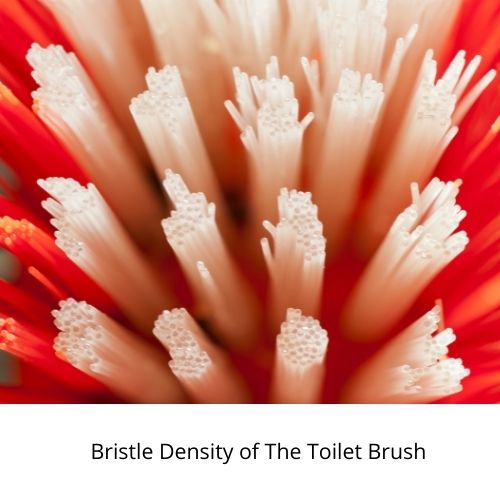

Bristle Density of The Toilet Brush

The type of bristles on a toilet brush is essential for two reasons. First, the bristles need to be dense enough to scrub away tough stains. Second, the bristles should be soft enough not to scratch the toilet bowl.

Most toilet brushes have nylon or polyester bristles. These synthetic materials are durable and practical at scrubbing away stains. However, some toilet brushes have natural bristles like hog’s hair or horsehair. These natural bristles are softer and less likely to scratch the toilet bowl.

Length of The Bristles

The length of the bristles is also vital to consider. Toilet brushes with longer bristles can reach deeper into the toilet bowl to scrub away tough stains. However, shorter bristles are easier to clean and less likely to get tangled.

Material of the Toilet Brush

The material of the toilet brush handle is also important. The type of handle you choose depends on your personal preferences. Some toilet brushes have plastic handles, while others have metal or wooden handles.

Length of the Toilet Brush Handle

The length of the toilet brush handle is also significant to consider. Toilet brushes with longer handles are easier to reach into the toilet bowl. However, shorter handles are more compact and easy to store.

Most toilet brushes have handles that are between 12 and 18 inches long. If you have many reaches, you may want to choose a toilet brush with a longer handle. However, if you have limited storage space, you may want to choose a toilet brush with a shorter handle.

Durability of The Toilet Brush

Toilet brushes need to be durable to withstand repeated use. Look for a toilet brush with a sturdy handle and bristles that are securely attached to the handle.

Avoid toilet brushes made from cheap materials like wood, as they are more likely to break. The toilet brush should also be made from durable materials like plastic or metal. If you want a toilet brush that is durable and resistant to rust and corrosion, you may want to choose a toilet brush made from stainless steel.

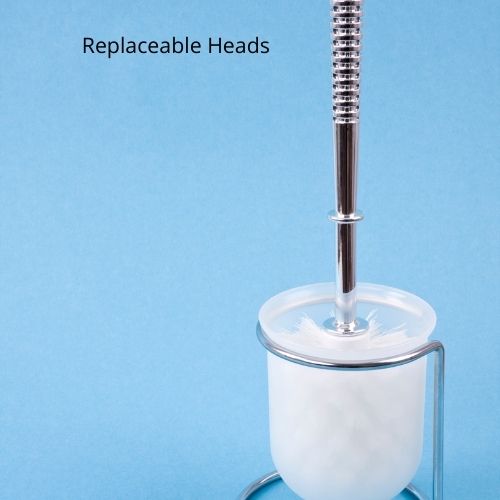

Replaceable Head

Some toilet brushes come with replaceable heads. It is a handy feature, as it allows you to replace the head of the toilet brush when it becomes dirty or worn out. Replaceable heads are also helpful if you have a toilet brush with long bristles, as the bristles will eventually wear out.

Flexibility of The Toilet Brush

The flexibility of the toilet brush is also essential to consider. A flexible toilet brush can easily reach into tight spaces and corners. It is crucial for cleaning hard-to-reach areas like the toilet bowl rim.

Scrubbing Head of The Toilet Brush

The scrubbing head is another crucial factor to consider while choosing a toilet brush. Some toilet brushes have round scrubbing heads, while others have triangular ones.

Round scrubbing heads effectively clean large areas, while triangular scrubbing heads are better at cleaning tight spaces and corners.

Handle of The Toilet Brush

The toilet brush handle should be comfortable to hold and easy to grip. Look for a toilet brush with a textured or non-slip handle. It will help you keep a firm grip on the toilet brush, even when your hands are wet. The handle should also be long enough to reach the toilet bowl easily.

Price of The Toilet Brush

When choosing a toilet brush, it’s essential to consider your needs and budget. Toilet brushes range in price from Rs 100 onward. If you wish to buy a toilet brush with remarkable durability and flexibility, then you may have to spend a bit more. However, there are many affordable toilet brushes available on the market.

Toilet Brush FAQS

What type of toilet brush is best for you?

The best toilet brush for you depends on your needs and preferences. Consider the bristles, material, length, durability, flexibility, and scrubbing head when choosing a toilet brush.

What is the best way to store a toilet brush?

Toilet brushes can be stored in a dry and ventilated area. Avoid storing toilet brushes in humid or wet areas, as this can cause the bristles to become moldy. It’s also vital to keep toilet brushes away from children and pets.

How often should you replace your toilet brush?

It would help if you replaced your toilet brush every few months or when the bristles become worn out.

What is the best way to clean a toilet brush?

To clean a toilet brush:

- Rinse it with hot water and soap.

- Avoid using harsh chemicals, as this can damage the bristles.

- Allow the toilet brush to air dry after cleaning.

How do these brushes differ from each other?

The main difference between toilet brushes is the type of bristles. Some toilet brushes have natural bristles, while others have synthetic bristles. Natural bristles are usually softer and more gentle on your toilet bowl, while synthetic bristles are more durable and practical at scrubbing tough dirt and grime.

What is the most crucial factor to consider when choosing a toilet brush?

Toilet brushes come in different shapes and sizes, so it’s essential to choose the best suits your needs. When choosing a toilet brush, the most crucial factor is the bristles. Ensure that the bristles are dense, durable, and flexible enough to reach all areas of your toilet bowl.

What are the benefits of using a toilet brush?

Toilet brushes are beneficial because they help you clean your toilet bowl effectively. They also allow you to reach tight spaces and corners that are difficult to clean with a toilet brush. Additionally, toilet brushes can help you remove tough stains and odors from your toilet bowl.

What are the risks of not using a toilet brush?

If you do not use a toilet brush, you may not clean your toilet bowl as effectively. It can lead to a build-up of dirt, grime, and bacteria in your toilet bowl. Additionally, not using a toilet brush can also cause tough stains and odors to develop in your toilet bowl.

What size toilet brush do I need?

The size of the toilet brushes you need depends on the size of your toilet bowl. If you have a small toilet bowl, you may need a smaller toilet brush. Conversely, if you have a giant toilet bowl, you may need a larger toilet brush.

Now that you know all about the different types of toilet brushes and their features, it’s time to make a purchase. We hope this buying guide has helped you determine which brush is best for your needs.

P.S: Borghi’s Star Delta Double Hockey Brush Machine is the perfect solution to manufacture double hockey toilet brushes. It is the latest and most advanced machine for manufacturing double hockey toilet brushes. Star Delta has been designed with consumers’ needs in mind and allows toilet brush manufacturers to produce high-quality brushes quickly and easily.