Need For Manual Brush Making Machines

While the trend in many industries is towards increasing automation, there remains a critical role for manual brush-making machines. Here’s why these machines are indispensable for producing high-quality, specialized brushes, with a spotlight on the THETA Brush from Borghi India—a standout example of innovation in manual brush-making technology.

Customization at Its Core

Technical brushes vary significantly in their application, necessitating a level of customization that goes beyond the capabilities of most automated systems. Whether it’s adjusting bristle length, density, or pattern, manual machines offer the precision required to meet exacting specifications. This ability to design each brush to specific industrial needs is not just a matter of quality, but can be crucial for the functionality of the equipment these brushes are designed to work with.

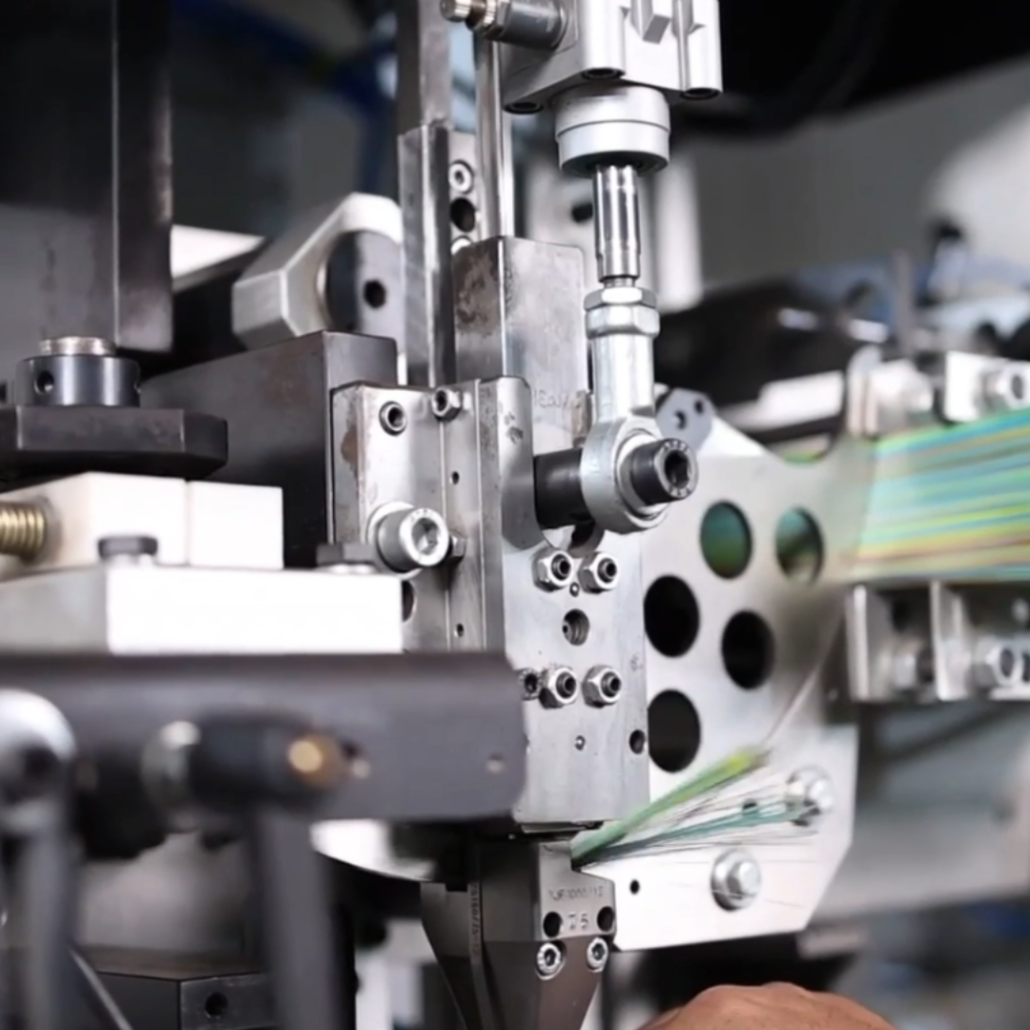

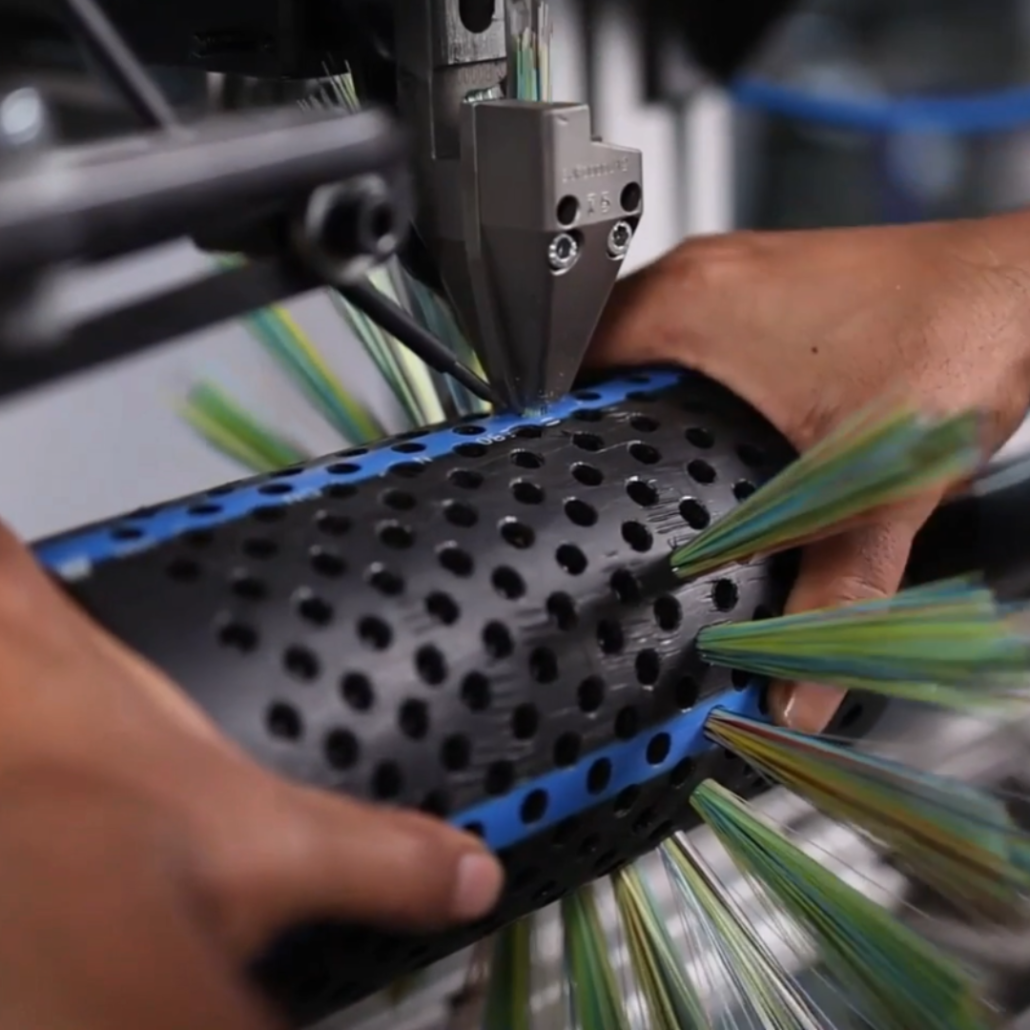

Introducing the THETA MANUAL from Borghi India, a vertical tufting machine that exemplifies this bespoke approach. It’s specifically designed for the production of brushes with pre-drilled blocks, allowing for perfect customization. The operator can manually position the block using a mechanical pointer, ensuring precise alignment with the filling tool that inserts the bristles.

Navigating Complex Designs

Some technical brushes have complex, non-standard shapes that automated machinery simply cannot produce effectively. Manual brush-making machines allow for adjustments on the fly, which is essential when creating designs that may need iterative modifications during the initial production phases. This flexibility is particularly valuable in innovative industrial applications where standard solutions do not suffice.

The THETA MANUAL supports the production of flat brushes as well as more complex shapes like cylindrical and disc brushes. Its brush holder, equipped with a simple plate for flat brushes and additional attachments for other shapes, offers versatility and adaptability in brush design.

Small Batch Efficiency

Often, technical brushes are required in limited quantities for highly specialized applications. Manual production is significantly more cost-effective in such scenarios. Unlike automated systems, which require extensive setup and are optimized for large-scale production runs, manual machines like the THETA MANUAL can produce small batches without incurring overwhelming costs. This makes them ideal for development or for industries where the brushes are used in niche applications.

Material Mastery

The range of materials used in technical brushes is broad and includes metals, natural fibers, and advanced synthetic materials. Each type of material presents unique challenges, from handling and processing to the integration into the final brush design. Manual machines provide the gentle touch and adaptability needed to work with diverse materials, ensuring that the structural integrity and performance characteristics of the brushes are maintained.

Uncompromised Quality Control

For industries relying on technical brushes, quality cannot be compromised. The potential cost of a malfunctioning brush in a manufacturing process can be astronomical, not just in terms of money but in downtime and product quality issues. Manual brush-making allows operators to oversee each step of the manufacturing process closely, performing quality checks and making immediate adjustments as needed. This hands-on approach ensures each brush is up to the standard required before it ever leaves the production floor.

The THETA MANUAL facilitates this level of control with its foot-pedal activated filling operation, which allows the operator to stay engaged and responsive throughout the production process.

Conclusion

The role of manual brush-making machines in the production of technical brushes is a perfect example of how traditional manufacturing techniques continue to hold value in a modern industrial era. Balancing automation with manual expertise allows industries to harness the best of both worlds—embracing efficiency while ensuring each product meets the unique demands of its application. In a world that values precision, customization, and quality, the THETA MANUAL from Borghi India stands out as a vital tool in the craft of manual brush making.